Cloud,Applications,IT Outsourcing,Analytics and Engineering

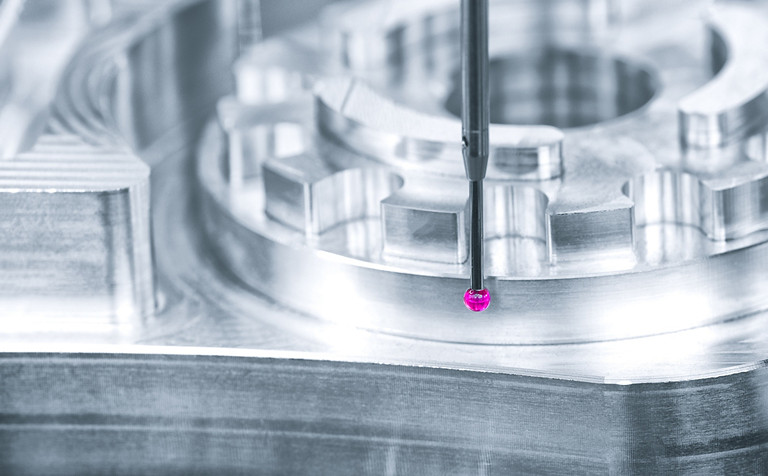

As manufacturers shift to the digital landscape, they face ongoing challenges in integrating new solutions with their existing IT systems and practices. DXC Technology helps our manufacturing customers meet these challenges by designing and deploying digital solutions at scale, modernizing their technology to improve production performance and maximize return on investment. Not only that, but DXC shares our expertise through our consulting services, workshops and proofs of concept, enabling our customers to efficiently and effectively plan for their migration.

Our customers around the world benefit from our industry-leading partnerships and digital talent ecosystem, attaining innovative solutions with scale, speed and agility.

“As a manufacturer, we need to consider both IT and OT security. Not only do we need to protect our IT environment, but we also need to secure the operational technologies that automate our manufacturing processes. We look to DXC to help instill security throughout the organization and identify ways to cost-effectively maintain our security posture.”

Rodney Masney

Chief Information Officer

O-I Glass

Cloud,Applications,IT Outsourcing,Analytics and Engineering

Applications,Cloud,IT Outsourcing,Security,Modern Workplace

Cloud,Applications,IT Outsourcing,Modern Workplace

Discover how to tackle technical debt as part of your modernization efforts.

Explore Reframing Technical Debt

Read the DXC research report Embracing modernization: from technical debt to growth