Analytics & Engineering

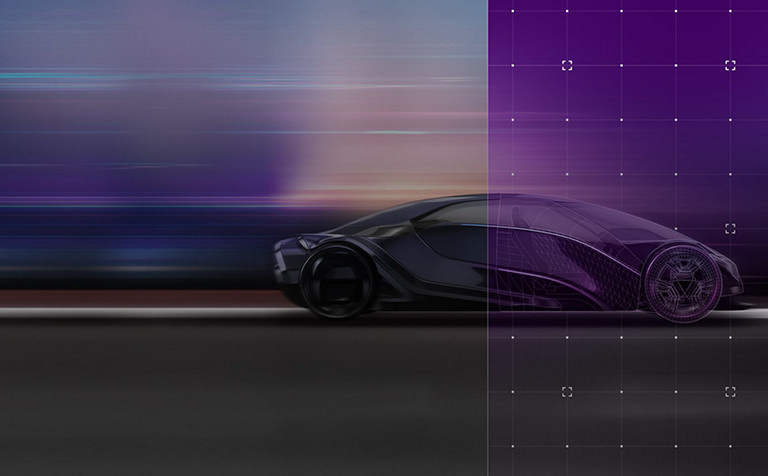

DXC Technology empowers customers worldwide to drive competitive advantage and navigate change. With expertise spanning autonomous drive, connected mobility, digital cockpit, UX, and testing and validation, DXC helps automakers, Tier 1 suppliers and key partners accelerate the shared, personal, connected and intelligent mobility of the future.

We work with our customers to support your transformation to become innovative digital businesses at the convergence of AI, autonomous mobility, connected infrastructure and digitization.

We design and co-create products and services that help automotive companies make the transformation to sustainable mobility.

Data management is critical to autonomous driving development. Today, data and metadata management for AD/ADAS is increasingly moving from on-premises systems to the cloud. In this new paper, Dr. Günter Koch examines what’s driving the preference for cloud, identifies the challenges and evaluates hybrid solutions and how they could be optimized for “best-of-breed” implementation.

Automakers and their suppliers face a new and serious challenge: conforming to the growing number of environmental, societal and governance (ESG) regulations that affect the industry. Learn how DXC Technology’s innovations help vehicle manufacturers with ESG regulatory compliance.

“We have been working with Ferrari for several years on their essential infrastructure, and we are proud to move to a partnership that includes guiding them to their technology future. We are committed to innovating technology that transforms the vehicle information capabilities and enhances the driving experience for all.”

Michael Corcoran

Global Lead, Analytics & Engineering, DXC Technology

Analytics & Engineering

Analytics & Engineering